As the fall harvest begins, farms across the U.S. will begin pumping manure from the pits of swine and beef barns. The surprise of a firm crust or solids build-up can mean increased time spent agitating pits, lower nutrient utilization, and higher application costs. While manure is a by-product of animal production, high quality manure doesn’t just happen, it takes a bit of work and expertise.

Manure has become an important part of most farm’s crop nutrient programs. Farmers are not only looking at ways to reduce crusts and increase uniformity of the manure, but also want to make sure important nutrients like nitrogen and phosphorus are available from the manure.

Having the proper level of microbial activity in the pit will ensure that solids are more rapidly converted to liquids, sludge does not form and crusts will not occur. Healthy Farms, in Worthington MN has multiple products that have been successful in reducing sludge and crusts in pits and lagoons. Activator Plus provides a fast acting release of bacteria that start working instantly on the unwanted crust layer. This constant enzyme production from the microbial activity results in a crust free nutrient mix with improved nutrient value and liquefaction of the slurry allowing for improved pump out and field application.

The AgraSphere and AgraSlat are biodegradable products that deliver microbes which attack the sludge and liquefy the solids. Healthy Farms introduced the AgraSlat as an advanced delivery system for filtered livestock facilities with no access point for the AgraSphere. Filtered facilities with limited access to pits are easily treated with the new AgraSlat technology which delivers the treatment directly through the slats to the pits. The unique delivery system of the AgraSphere and AgraSlat allows the products to sink to the bottom of the pit, treating more layers of the manure than if the product was just placed on the top layer of the pit. The time release technology within the AgraSphere and AgraSlat provides months of continual inoculation of bacteria resulting in increased microbial activity within the pit improving the environment within the barn through reduced odors and insects. The new addition of the Beef and Dairy AgraSlat has the technology and convenience of the AgraSlat but is specifically formulated for liquification of cattle manure.

The AgraSphere and AgraSlat are biodegradable products that deliver microbes which attack the sludge and liquefy the solids. Healthy Farms introduced the AgraSlat as an advanced delivery system for filtered livestock facilities with no access point for the AgraSphere. Filtered facilities with limited access to pits are easily treated with the new AgraSlat technology which delivers the treatment directly through the slats to the pits. The unique delivery system of the AgraSphere and AgraSlat allows the products to sink to the bottom of the pit, treating more layers of the manure than if the product was just placed on the top layer of the pit. The time release technology within the AgraSphere and AgraSlat provides months of continual inoculation of bacteria resulting in increased microbial activity within the pit improving the environment within the barn through reduced odors and insects. The new addition of the Beef and Dairy AgraSlat has the technology and convenience of the AgraSlat but is specifically formulated for liquification of cattle manure.

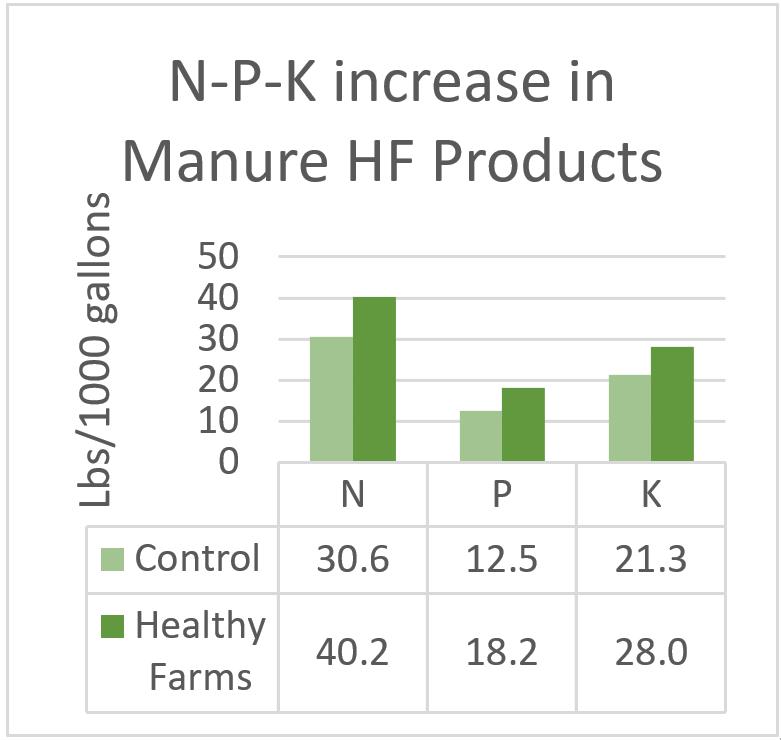

The three-year study of Healthy Farms pit products on the right illustrates proven ROI with an average annual increase in macronutrients of over 20% compared to untreated manure

The increase in nutrients within the manure can be attributed to cellular remediation where cells are capturing the ammonia rather than letting it volatize into the environment as free ammonia. The increase in organic cellular nitrogen results in more available nitrogen being delivered to the plant and financially benefitting the producer. In addition to increased available nitrogen, producers using Bioverse microbial treatments have also reported increases of plant transferable phosphorus and potassium.

Capturing the value of manure reduces application levels and costs of commercial fertilizer. A better functioning pit provides a higher-quality environment for both pigs and barn workers. High value manure and better quality environment – a winning situation for everyone!

- Log in to post comments