It is well-known that once corn silage is harvested and ensiled, it takes some time before the silage will reach its optimal feed quality. A key goal when ensiling corn silage is to reduce oxygen and raise acidity rapidly so that lactic acid bacteria will go to stabilize and preserve the silage. I often hear people say that corn silage is well-fermented after three weeks in storage and that it’s okay to go ahead and start feeding it. While it is true that the largest percentage of total fermentation takes place in the first three weeks of storage, it is important to note that lactic acid, pH reduction and soluble protein will not reach the maximum levels until approximately four months after ensiling. Furthermore, acetic acid and soluble protein levels will continue to rise through six months of ensiling, while the digestibility of the starch within the corn silage will increase greatly over the first five to six months, with marginal increases thereafter.

Harvesting the corn silage crop at the correct maturity and whole plant dry matter is a crucial first step to achieving a great fermentation, along with the proper length of chop, kernel processing, use of an inoculant, packing well and covering the silage. When the crop is properly ensiled, fermentation begins.

Stages of fermentation

- Phase 1: Aerobic phase (0 to 2 days after ensiling). As much oxygen as possible should be eliminated from the silage by packing and sealing. The amount of oxygen remaining will depend on the moisture content, silo filling time, manual silo packing and the chop length of the silage. Even with the best harvest management in place, some oxygen will remain in the silage. During this initial phase, the remaining oxygen will be used up, as the cells in the forage take in the oxygen and turn it into carbon dioxide in a process known as cell respiration. Aerobic bacteria also use the remaining oxygen in this phase, combined with plant sugars, to create carbon dioxide, water and heat. This phase typically lasts one day, but it can take more or less time than that, depending on the ensiling practices. Well-packed and sealed silos will generally have a shorter aerobic phase (as little as a few hours), while poorly packed and sealed silos will have a longer aerobic phase. Long aerobic phases can be detrimental to the final forage quality. Long aerobic phases result in very high silage temperatures (in excess of 100 degrees Fahrenheit), high dry matter losses (due to the increased nutrients needed to fuel this phase), mold growth, mycotoxin production and Maillard reactions (browning of the forage, which convert digestible protein into bound, undigestible protein). The silage pH will begin to drop from 6.5 to 6.0 during this time.

- Phase 2: Lag phase (after completion of aerobic phase). After the remaining oxygen is used up, plant cells are broken down and used as a food source by bacteria. Plant enzymes break down complex carbohydrates, starch and fiber into simpler sugars that are easily used by bacteria. Enzymes also break down plant proteins at this time, making protein more soluble. The bacteria will use the cell juices produced during the lag phase to grow during the fermentation phase. Silage pH drops (and acidity increases) to around 5.7 to 5.5 at this time.

- Phase 3: Anaerobic fermentation phase (2 to 3 days after ensiling). When cell juices are available, oxygen has been eliminated and silage pH has declined to a level at which lactic acid bacteria can grow (i.e., below 5.7 pH). The lactic acid bacteria begin to grow, multiply, make lactic acid and some acetic acid, and increase silage acidity further. Lactic acid is stronger than acetic acid and, thus, decreases the silage pH more than acetic acid does. There are two types of lactic acid bacteria: homofermentative and heterofermentative. The homofermentative bacteria produce primarily lactic acid, while the heterofermentative bacteria produce lactic acid, acetic acid, ethanol and carbon dioxide. Homofermentative bacteria are more desirable as they work faster, saving more nutrients for the cow to use and for silage to be better preserved. Of the total acid in well-preserved silage, at least 70% should be lactic acid. The initial amount of lactic acid bacteria in the silage will be higher with warmer temperatures and higher silage moisture. The anaerobic fermentation phase usually takes about two weeks, and the silage cools to near ambient temperature.

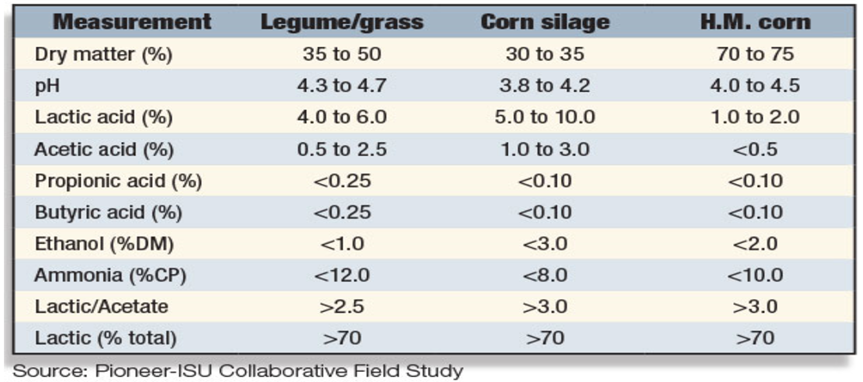

- Phase 4: Stable phase (around 21 days after ensiling). After completion of the anaerobic fermentation phase, corn silage pH should be within a range of 3.8 to 4.2, which is an indicator that corn silage has reached the stabile phase, where silage is preserved and bacteria have slowed or stopped growing. If the available sugars are depleted before the silage reaches low pH, the fermentation will stop before the silage reaches the stabile phase, leading to an increased potential for a poor fermentation profile, decreased palatability and fewer nutrients available to the cow. Increases in forage quality can continue to improve through four to six months in storage due to continued bacterial action and kernel enzymes helping to solubilize protein. If the crop is harvested at less-than-ideal conditions, Lactobacillus buchneri inoculants can be used to improve the stability of silages when they are exposed to air. These added organisms result in a “controlled” fermentation that produces moderately higher concentrations of acid, which can help to limit the growth of wild yeast and mold when silages are exposed to air at feed-out. Included below (in Table 1) are a few important guidelines for well-preserved, ensiled feeds.

Table 1. Recommended fermentation profile for ensiled feed

Starch availability

Ruminal starch digestibility in corn silage varies by year and location and is often influenced by many factors, including the stage of corn maturity at harvest, kernel processing, storage time, hybrid selection and growing conditions. When the intersection of optimal whole-plant dry matter, starch content and fiber digestibility is achieved, the starch digestibility of the corn silage is typically at its lowest point. Therefore, we can potentially see milk production decline when green chop silage is fed without corrective measures to the ration.

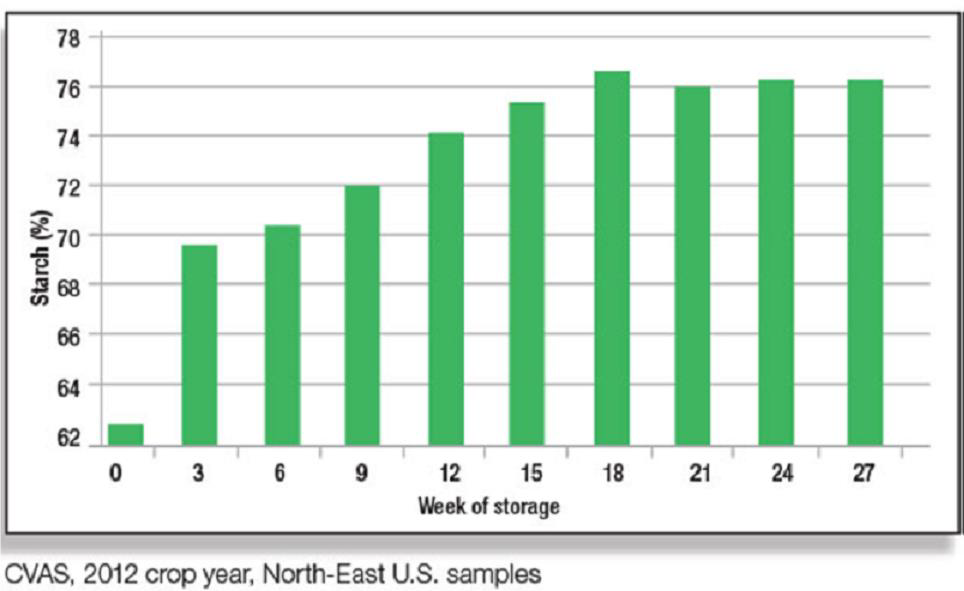

Typically, after the first few months of the silage being ensiled, the starch digestibility greatly increases (Graph 1), thereby enhancing the starch fermentability of the ration. This enhancement continues while the silage remains in storage due to the increases in soluble protein over time. This increase in soluble protein (the breakdown of the corn’s zein protein or the prolomin protein covering the starch granules) continues to improve the starch digestibility/availability. Without routine testing of the silage, the starch digestibility can be a bit of an unknown and can greatly impact your ration, either positively or negatively, depending on the rate of digestion of the silage in its current state. Therefore, routine testing of rumen-degradable starch is recommended to ensure that the ration the cows are eating contains the appropriate amounts of digestible starch to maximize performance.

Graph 1. Impact of storage time on starch availability

Check with your nutritionist for their thoughts on your herd’s starch digestibility and potential. If starch digestibility has room to gain, check the corn grain particle size and consider adding raw corn starch, rolled or ground softer grains (wheat or barley) or other research-backed nutritional options to aid in improving your ration’s starch digestibility and availability. Many dairies keep up to six months of silage carryover from the previous crop, allowing the silage to stabilize and the starch digestibility to maximize before feeding. For assistance with planning your forage inventory needs, and for more information on how to optimize forage quality on your farm, please reach out to your nearest Hubbard dairy team member.

- Log in to post comments