BULLETPROOF® Bunk Stabilizer maintains the freshness of total mixed rations (TMR) that contain fermented feeds. The anti-oxidants in BULLETPROOF Bunk Stabilizer inhibit the growth of undesirable yeast and other spoilage organisms that can cause heating and reduced feed intake.

BULLETPROOF Bunk Stabilizer contains sulfur containing anti-oxidants which limit the growth of undesirable yeast and molds by acting as oxygen scavenger. Wild type yeast are present in fermented forages and high moisture grains that are included in a TMR. The mixing action of the TMR exposes these undesirable yeast to oxygen. Left unchecked, the yeast will cause the TMR to heat. In addition, other sugar containing ingredients commonly added to the TMR will be used by the yeast as an energy source. The combined affect of heating and nutrient loss often results in lower feed intake and reduced milk production.

Forage Management:

- Keep a smooth even surface to the feeding face of silages bunkers.

- Size the storage structure to allow adequate removal of feedstuffs each day.

- Feed the TMR multiple times per day.

- Keep the surface area of the bunk or trough smooth to prevent slime formation and pockets of feed spoilage.

If any of the above are difficult to achieve the addition of BULLETPROOF Bunk Stabilizer will result in a fresher TMR with more consistent feed intake.

BULLETPROOF Bunk Stabilizer is added to the TMR at time of mixing to maintain freshness and cow acceptance. Heating of the TMR can occur due to the growth of yeast and molds. This heating is most common in the warmer months.

Use Bulletproof Bunk Stabilizer when there is risk of heating in:

Dairy Cattle

- Lactating cow diets

- Dry cow diets

- Young stock diets

Beef Cattle

- Receiving diets (High Forage Diets)

- Growing diets

- Finishing diets

Application Rates:

Apply 1-3 pounds per ton of TMR.

Apply 2-3 pounds per ton when there is increased risk of TMR heating due to the inclusion of warm ingredients and/or high ambient temperatures.

Increased Feeding Risk Factors:

- High corn silage diets that have high yeast counts.

- Drier diets due to increased oxygen exposure.

- High ambient temperature.

- Diets that contain heated or partially fermented forage.

Product Options

50 pound poly-lined bag.

Nutrient Analysis

Sulfur, min.............................21.0%

HANDLING: Keep bags sealed when not in use. Store bags in a cool, dry location. Keep away from acids. BULLETPROOF Bunk Stabilizer can be applied using a scoop or pail that contains a known weight of product. Multiply the tons of TMR in the mixer by the desired pounds per ton to arrive at the total amount need per mixer load.

BULLETPROOF Bunk Stabilizer may be applied across the top of each load of TMR or added to the grain portion of the mix. Efforts should be made to get even distribution.

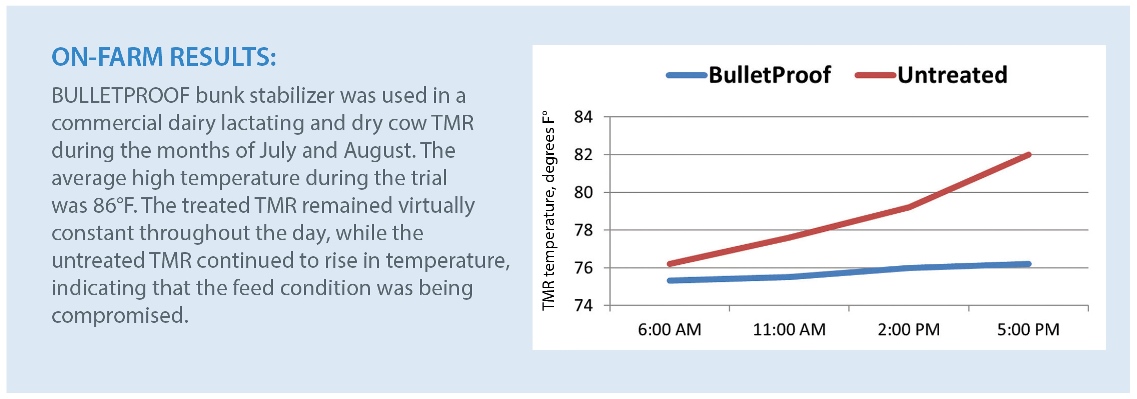

During a 2 month field trial conducted on a commercial Indiana dairy, BULLETPROOF Bunk Stabilizer was added to the TMR of the high group during the summer months. Throughout the day, the temperature of the treated TMR and an untreated TMR were recorded daily at 6 AM, 11 AM, 2 PM, and 5 PM using an infrared temperature thermometer. The use of BULLETPROOF Bunk Stabilizer maintained the temperature and freshness of the TMR. The chart shows the average temperature of each treatment.

EXTENDED EXPOSURE MAY IRRITATE SKIN, EYES AND RESPIRATORY TRACT. MAY CAUSE ALLERGIC REACTION IN SOME ASTHMATICS OR INDIVIDUALS SENSITIVE TO SULFUR.

In the event of contact wash eyes and skin with water for 15 minutes. Get medical attention if symptoms appear. If inhalation occurs move to fresh air.

DISCLAIMER: Due to weather and management factors that are beyond our control, no expressed or implied warranty are made for this product.

Shelf Life: 3 years with proper storage.

#29099—BULLETPROOF® Bunk Stabilizer